Industry: Renewable Energy (Energy Storage)

Challenge: Ensure the safe and efficient operation of a new airtight energy storage container concept, under extreme temperature conditions. The container relies solely on air conditioning units for temperature control and houses critical energy storage components that require a specific temperature range for optimal performance and longevity.

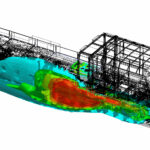

Solution: A thermal analysis was conducted to evaluate the air conditioning system’s ability to manage heat load and maintain a safe operating environment within the container under extreme conditions, defined as an ambient temperature of 45°C and high solar radiation.

Results:

- Heat Load and Cooling Capacity: The analysis confirmed that the air conditioning system can handle the container’s heat load, even under extreme conditions. This ensures the system has enough reserve capacity to maintain safe operating temperatures.

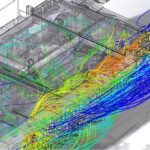

- Energy Storage Component Cooling: The study identified the optimal air flow rate and pressure drop needed for effective cooling of the energy storage components. However, air conditioning operation slightly reduces the achievable air flow rate.

- Cooling Strategy: Directing cooler air behind the energy storage components proved to be a successful strategy for maintaining a safe operating temperature in this critical area.

- Component Placement and Airflow: Strategic positioning of the energy storage components is crucial for optimal airflow. This prevents air from escaping through unintended gaps and ensures proper circulation throughout the container.

- Flow Distributors: The study concluded that flow distributors are unnecessary in the current design. The existing layout provides sufficient air flow distribution, and adding them would only create unwanted back pressure.

- Air Conditioning Back Pressure: The analysis measured the back pressure within the system under air conditioning operation at a specific value and air flow rate.

The current air conditioning system demonstrated adequate capacity to cool the container effectively under extreme heat conditions. The use of cooler air, without requiring active housing fans for the components, ensures a safe operating environment for the energy storage system, maximizing its performance and lifespan.

Do you face challenges in maintaining temperature control for critical equipment in harsh environments? Thermal analysis can help you design and optimize cooling systems for your specific needs. Contact us today to discuss how our expertise can help you ensure optimal performance and protect your valuable assets.