Industry: Manufacturing (Machinery, Industrial Equipment)

Challenge: Cooling units are critical components in many industrial systems, responsible for dissipating heat and ensuring optimal system operation. The structural integrity of these units, particularly the welds joining various components, is crucial for safe and reliable performance. Traditional methods of structural analysis, such as manual calculations and physical testing, can be time-consuming and limited in scope.

Solution: Finite element method (FEM) simulations using advanced engineering software like ANSYS provide a powerful and efficient solution for analyzing weld strength in cooling units. This approach allows engineers to:

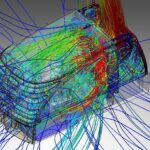

- Create a digital replica: Develop a detailed 3D model of the cooling unit geometry, including welds and surrounding components.

- Apply realistic loads: Simulate the various loads acting on the unit during operation, such as static weight, pressure from the cooling fluid, and dynamic vibrations.

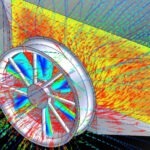

- Analyze stress distribution: The FEM software discretizes the model into a mesh and calculates the stress distribution throughout the structure, focusing on critical weld locations.

- Identify potential failure points: By visualizing the stress concentration areas (usually depicted by von Mises stress plots), engineers can pinpoint welds susceptible to failure under expected loading conditions.

Benefits of FEM Simulations for Weld Analysis:

- Virtual testing environment: FEM simulations create a virtual test bed, eliminating the need for physical prototypes and destructive testing. This allows for:

- Efficient evaluation of different weld designs and configurations.

- Rapid iteration on weld parameters like size and material selection.

- Cost-effective assessment of various loading scenarios.

- Improved design optimization: By analyzing stress distribution in welds, engineers can:

- Optimize weld geometry and size to ensure sufficient strength and fatigue life.

- Select appropriate weld materials based on the specific loading conditions.

- Minimize weld weight while maintaining structural integrity.

- Enhanced safety and reliability: Proactive weld analysis using FEM simulations helps to:

- Prevent catastrophic weld failures that can lead to system downtime and potential safety hazards.

- Ensure the cooling unit operates reliably throughout its intended lifespan.

Outcomes:

FEM simulations can significantly improve the design and manufacturing process of cooling units. By identifying potential weak points in welds early in the design phase, engineers can:

- Reduce the risk of weld failures: Optimized weld designs lead to a lower likelihood of cracks or other failure mechanisms during operation.

- Enhance product quality: FEM analysis ensures the cooling unit meets all structural requirements and delivers reliable performance.

- Minimize manufacturing costs: Optimized weld designs can reduce material usage and streamline the welding process.

Impact on Manufacturing:

Implementing FEM simulations for weld analysis in cooling unit design offers several advantages for manufacturers:

- Improved product safety and reliability: By proactively addressing weld strength, manufacturers can ensure their cooling units function safely and reliably in various applications.

- Reduced development costs: Virtual testing eliminates the need for expensive physical prototypes and destructive testing, leading to cost savings.

- Enhanced product performance: Optimized weld designs contribute to a more efficient and durable cooling unit.

Take the Next Step:

Are you a manufacturer facing challenges in ensuring the structural integrity of welds in your cooling units? Our engineering team can help! We leverage advanced FEM simulation techniques to analyze and optimize weld designs, leading to:

- Safer and more reliable cooling units

- Reduced development costs

- Improved product performance

Contact us today to discuss your specific needs and discover how FEM simulations can benefit your cooling unit design process.