Intake Manifold Shape Optimization with CFD Analysis

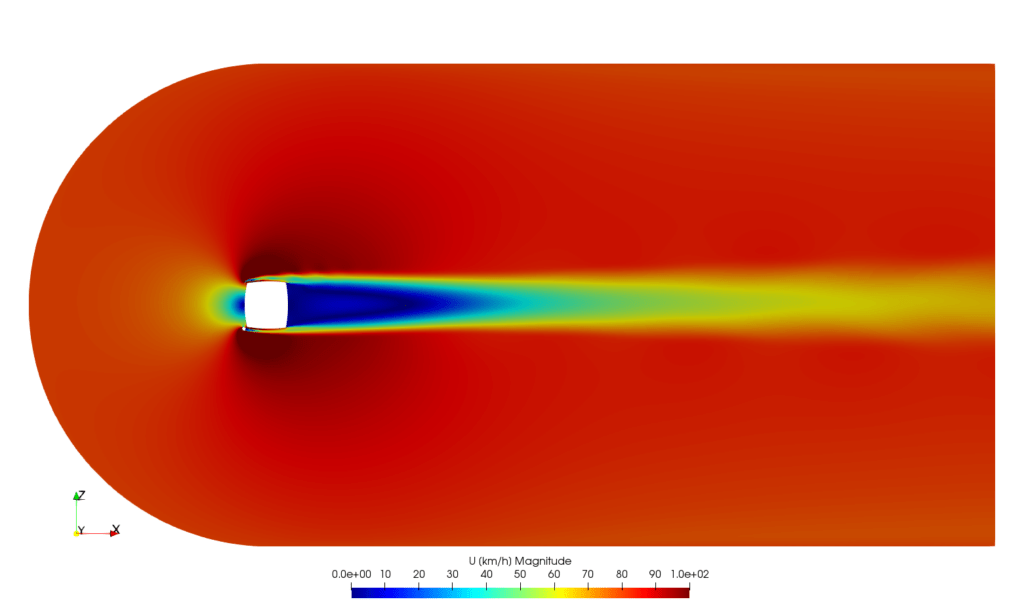

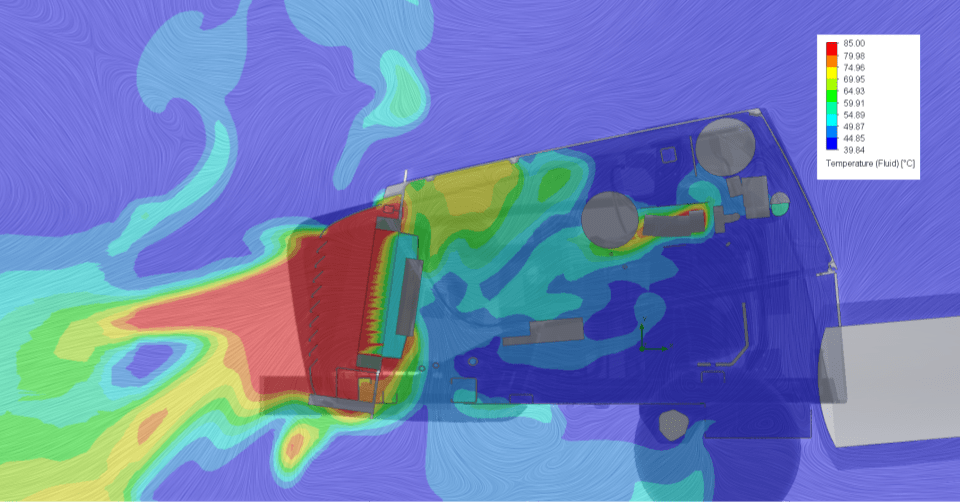

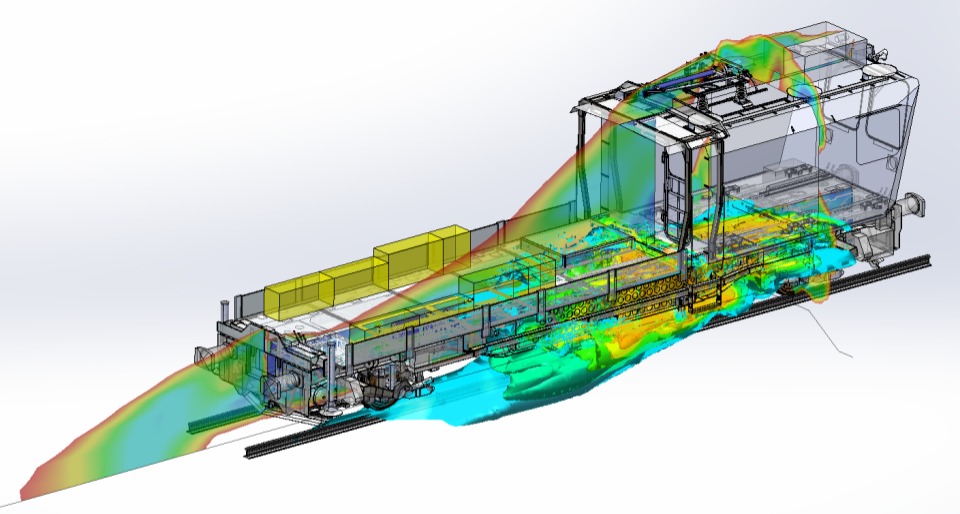

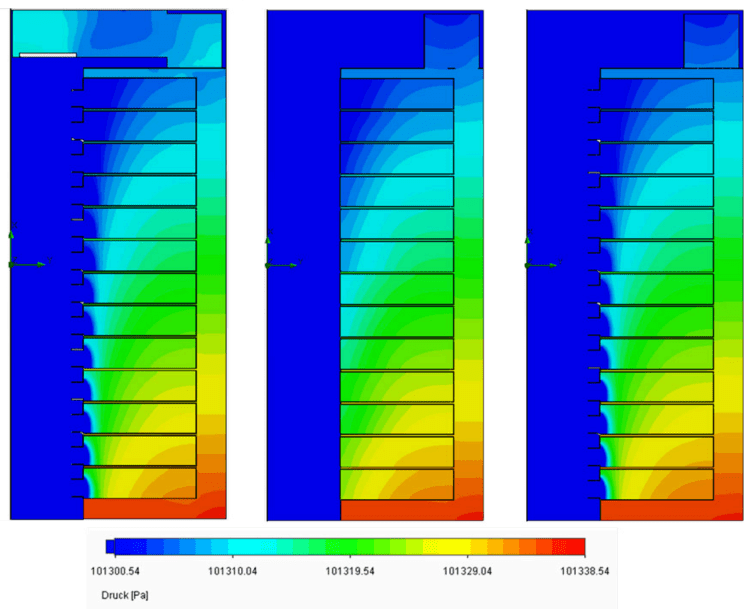

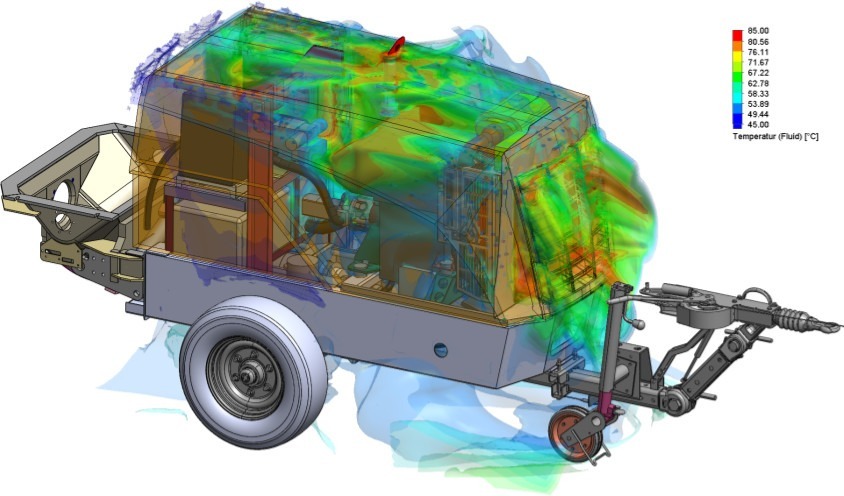

Industry: Agricultural Equipment Challenge: This study aimed to optimize the design of an intake manifold for a specified vehicle model. The goal was to improve airflow characteristics, minimize drag forces, and reduce side force oscillations experienced by the vehicle. Solution: Computational fluid dynamics (CFD) simulations were employed to analyze the performance of six different intake […]