Industry: Renewable Energy (Energy Storage)

Challenge: Ensure the optimal cooling performance of an energy storage container by analyzing the pressure drop associated with varying gap widths between the battery modules. This analysis is crucial for determining the impact of aisle width on the cooling system’s effectiveness and reducing design uncertainties.

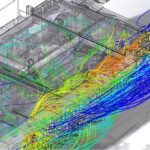

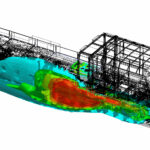

Solution: Computational fluid dynamics (CFD) simulations were conducted to investigate the pressure drop as a function of the wall distance between the battery modules. The simulations evaluated the cooling behavior, particularly the temperature distribution, and assessed the influence on pressure drop.

Results:

- Pressure Drop and Wall Distance: The analysis revealed a clear correlation between the pressure drop and the wall distance. As the gap width decreases, the pressure drop increases due to increased frictional resistance and flow disturbances.

- Cooling Performance: The CFD simulations demonstrated that the cooling effectiveness remains satisfactory even with a reduced wall distance. The temperature distribution across the battery modules was relatively uniform, indicating adequate heat dissipation.

- Minimum Recommended Gap Width: Based on the results, a minimum recommended gap width of 10 cm was established. This ensures that the pressure drop remains within acceptable limits and that the cooling performance is not compromised.

Conclusion:

The study concluded that narrowing the gap between the battery modules does not significantly impact the cooling performance of the energy storage container as long as the minimum recommended gap width of 10 cm is maintained. This provides valuable insights for optimizing container design and ensuring efficient temperature management of the energy storage system

Looking for innovative solutions to optimize cooling systems in your energy storage containers? Our expertise in CFD analysis can help you design containers that balance space efficiency with effective temperature management. Contact us today to learn more about how we can help you create reliable and efficient energy storage solutions.