Industry: Construction Equipment (e.g., Concrete Pumps, Generators)

Challenge: Manufacturers of construction equipment face a constant struggle to balance noise reduction with optimal engine performance and cooling efficiency. Muffler placement within the exhaust shaft plays a crucial role in achieving this balance. Traditional methods of physical testing and experimentation can be time-consuming and resource-intensive.

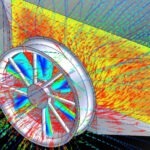

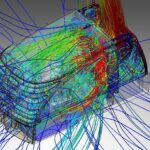

Solution: Advanced computational fluid dynamics (CFD) simulations offer a powerful alternative for optimizing muffler placement. Our engineering team partnered with a leading manufacturer of construction equipment (Company Name anonymized) to analyze the airflow and pressure distribution within their exhaust shaft for various muffler configurations. This virtual testing environment allowed us to assess the impact of different muffler placements on:

- Volume Flow Rate: Evaluate the effect on the overall airflow through the exhaust shaft, ensuring adequate ventilation for engine cooling.

- Backpressure: Analyze the pressure buildup within the exhaust system to prevent it from hindering engine performance or cooling efficiency.

Benefits of CFD Simulations for Muffler Placement Optimization:

- Virtual Testing Environment: CFD simulations create a virtual environment replicating real-world operating conditions. This allows engineers to:

- Analyze airflow patterns and pressure distribution within the exhaust shaft for various muffler positions.

- Identify areas of potential airflow restriction or excessive backpressure.

- Virtually test different muffler placements without the need for physical prototypes.

- Data-Driven Decision Making: By analyzing various scenarios, CFD simulations provide valuable insights to optimize muffler placement for:

- Reduced Noise Emissions: Achieve significant noise level reduction while maintaining adequate airflow and backpressure.

- Improved Engine Performance: Ensure minimal backpressure to maintain engine efficiency and minimize wear and tear.

- Enhanced Cooling Efficiency: Optimize airflow through the exhaust shaft to prevent overheating and ensure proper engine cooling.

Outcomes:

The CFD analysis in this project led to the identification of variant 3 as the optimal muffler placement for the construction equipment powerpack unit. This position achieved a significant balance between:

- Noise Reduction: Minimized noise emissions for improved operator comfort and compliance with noise regulations.

- Airflow Efficiency: Maintained adequate airflow through the exhaust shaft for effective engine cooling.

- Backpressure Control: Minimized backpressure buildup within the exhaust system to prevent any negative impact on engine performance.

Impact on Construction Equipment:

Implementing a CFD-optimized muffler placement strategy can lead to several benefits for construction equipment manufacturers and operators:

- Reduced Noise Pollution: Lower noise levels contribute to a safer and more comfortable working environment for operators and nearby personnel.

- Improved Engine Performance: Optimized backpressure ensures efficient engine operation, leading to reduced fuel consumption and extended engine lifespan.

- Enhanced Cooling Efficiency: Proper airflow through the exhaust shaft prevents overheating and protects critical engine components.

Are you facing challenges in optimizing muffler placement within your construction equipment’s exhaust shaft? We can help!

Our team of CFD experts leverages advanced simulation techniques to analyze and improve muffler placement designs, leading to:

- Reduced noise emissions

- Improved engine performance

- Enhanced cooling efficiency

Contact us today to discuss your specific needs and discover how we can help you create quieter, more efficient, and reliable construction equipment.

This case study exemplifies how CFD simulations offer a valuable tool for optimizing muffler placement in construction equipment exhaust shafts. By creating a virtual testing environment to analyze airflow and pressure distribution, engineers can design exhaust systems that achieve a balance between noise reduction, engine performance, and cooling efficiency.