Industry: Rail Transportation

This case study explores how Computational Fluid Dynamics (CFD) simulations can be used to analyze and improve the cooling system of a complex industrial component – an engine power pack for a vehicle.

Challenge: Ensure efficient heat dissipation within the power pack at cruising speed.

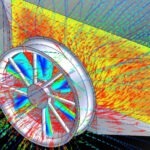

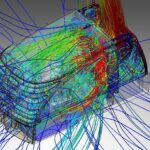

Solution: CFD simulations were employed to evaluate the flow, pressure, and temperature distribution of cooling air within the power pack enclosure (based on a simplified CAD model).

Benefits:

- Detailed Insights: The simulations provided a comprehensive view of how cooling air behaves inside the enclosure at high speeds.

- Optimized Performance: The analysis helped identify areas for improvement in the cooling system design, leading to more efficient heat transfer.

- Enhanced Reliability: By understanding the thermal behavior of the power pack, engineers can ensure optimal component performance and longevity.

Key Findings:

- Airflow Analysis: The simulations provided velocity distributions at cooler inlets and outlets, revealing potential areas for airflow optimization.

- Temperature Distribution: The analysis identified the temperature distribution throughout the enclosure, highlighting potential hot spots.

- Recirculation Zones: The simulations revealed recirculation zones above all coolers, indicating areas where cooling air might not be effectively utilized.

Next Steps:

Based on the CFD results, further investigation into the recirculation zones is recommended. This could involve refining the CAD model or conducting additional simulations to understand the impact of design modifications on airflow patterns and temperature distribution.

Conclusion:

This case study demonstrates the value of CFD simulations in analyzing and optimizing the cooling performance of complex industrial systems. By analyzing the flow, pressure, and temperature distribution of cooling air, engineers can design and implement efficient cooling solutions that ensure optimal component performance, reliability, and energy efficiency.

Do you face challenges in optimizing thermal management for your industrial equipment? CFD simulations can provide the insights you need to design reliable and efficient cooling systems. Contact us today to learn more!