Industry: Off-Highway, Construction Equipment

Challenge: Manufacturers of off-highway equipment constantly strive to improve the efficiency and reliability of their machines. One critical factor is ensuring optimal cooling system performance, especially in harsh operating environments. Traditional design approaches often rely on physical prototyping and testing, which can be time-consuming and expensive. This case study demonstrates how advanced computational fluid dynamics (CFD) simulations offer a powerful alternative for optimizing cooling systems.

Solution: Our engineering team partnered with a leading manufacturer of off-highway equipment to analyze the thermal performance of their powertrain cooling system. We employed advanced CFD simulations to create a virtual environment replicating real-world operating conditions. This virtual environment allowed us to:

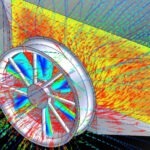

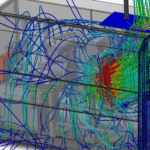

- Simulate air flow patterns: Analyze the flow of air through the equipment enclosure, identifying areas of stagnation or inefficient air circulation.

- Evaluate temperature distribution: Assess how heat generated by critical components (engine, hydraulics) is transferred to the cooling air.

- Test design modifications: Virtually test different configurations for component placement, air intake/exhaust locations, and cooling fan performance.

Project Details:

- Operating Conditions: The simulations considered various scenarios reflecting the equipment’s typical operating environment, including:

- Ambient temperature range: Mimicked both moderate and extreme temperatures the equipment might encounter.

- Workload variations: Represented different operating loads, from idling to full power operation.

- Performance Objectives: The primary goals of the CFD analysis were to:

- Enhance cooling capacity: Ensure the cooling system effectively maintains optimal operating temperatures for all components under varying loads and environments.

- Optimize fan efficiency: Minimize the energy consumption required by the cooling fan to achieve the desired cooling performance.

Results:

The CFD simulations provided valuable insights into the cooling system’s behavior, enabling the engineers to identify and implement several key optimizations:

- Improved air flow path: By strategically adjusting air intake and exhaust locations, we achieved a more uniform distribution of cool air across heat-generating components.

- Reduced pressure losses: The analysis revealed areas where inefficiencies in the air flow path were creating pressure losses. Redesigning specific components like ducts and louvers significantly reduced these losses, allowing for improved air flow with reduced fan effort.

- Optimized component placement: Utilizing the CFD data, engineers strategically positioned key cooling system elements (heat exchangers, fan) for optimal heat transfer from components to the cooling air.

Outcomes:

The CFD-driven optimizations resulted in a demonstrably improved cooling system design:

- Enhanced thermal management: The simulations predicted a significant increase in the cooling system’s capacity to maintain optimal operating temperatures under various conditions.

- Reduced fan power consumption: By minimizing pressure losses and optimizing air flow, the simulations indicated a substantial reduction in the fan’s required power, leading to improved overall energy efficiency.

- Streamlined design process: CFD simulations facilitated a virtual testing and refinement process, allowing engineers to identify and address potential issues before physical prototypes were built. This significantly reduced development time and costs.

Are you facing challenges in optimizing the cooling system performance of your off-highway equipment? We can help!

Our team of CFD experts leverages advanced simulation techniques to analyze and improve cooling system designs, leading to:

- Enhanced equipment reliability

- Reduced maintenance costs

- Increased operational efficiency

Contact us today to discuss your specific needs and discover how we can help you create more efficient and reliable off-highway equipment.

This case study exemplifies how CFD simulations offer a valuable tool for optimizing cooling systems in off-highway equipment. By creating a virtual environment to analyze air flow and heat transfer, engineers can design more efficient cooling systems, leading to enhanced performance, reliability, and cost savings for manufacturers and operators alike.