Industry: Construction Equipment

Challenge: A mortar machine’s cooling system was struggling to meet cooling requirements, leading to potential overheating issues. The existing fan design and airflow path were identified as contributing factors to the problem.

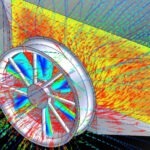

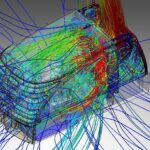

Solution: Computational fluid dynamics (CFD) simulations were employed to analyze the airflow patterns and thermal performance of the mortar machine. This allowed engineers to:

- Create virtual models: Develop detailed 3D models of the machine, including the engine, coolers, fan, and surrounding components.

- Simulate airflow: Replicate real-world airflow conditions, considering factors like air velocity, temperature, and turbulence.

- Analyze pressure loss: Identify areas of high resistance and quantify the overall pressure drop across the system.

- Evaluate thermal performance: Assess the effectiveness of heat transfer from various components, including the engine, coolers, and hydraulic system.

Benefits of CFD Simulations for Mortar Machine Optimization:

- Virtual Testing Environment: CFD eliminates the need for costly physical modifications and testing, saving time and resources.

- Detailed Flow Insights: CFD provides a comprehensive understanding of airflow patterns and pressure distribution within the machine, revealing areas for improvement.

- Predictive Capabilities: CFD can predict the impact of design changes on airflow and thermal performance, enabling proactive optimization.

- Design Optimization: By analyzing the impact of design parameters on airflow and heat transfer, engineers can optimize the machine for enhanced cooling efficiency and reduced pressure drop.

Outcomes:

CFD simulations revealed several critical issues contributing to the mortar machine’s cooling challenges:

- Excessive pressure loss: The existing fan design and airflow path resulted in significantly higher pressure loss than anticipated, limiting airflow and cooling capacity.

- Inefficient airflow: The air intake and outlet locations, as well as the presence of obstructions like the engine cover, disrupted airflow patterns and reduced cooling effectiveness.

- Internal heat buildup: The lack of ventilation within the machine led to internal heat buildup, further reducing the cooling capacity of the fan.

Proposed Solutions:

Based on the CFD results, engineers proposed several design modifications to address the cooling issues:

- Additional openings: Strategically placed openings in the machine’s cover and lower body would allow for increased airflow and reduced pressure loss.

- Fan optimization: A new fan with a higher efficiency and better airflow characteristics would be selected to match the modified airflow path.

- Thermal insulation: Implementing thermal insulation around the exhaust manifold would reduce heat transfer to the surrounding air, minimizing internal heat buildup.

Impact on Mortar Machine Performance:

Implementing the proposed design modifications based on CFD insights is expected to lead to significant improvements in the mortar machine’s cooling performance:

- Enhanced cooling efficiency: Improved airflow and reduced pressure loss would ensure adequate cooling of the engine, coolers, and hydraulic system.

- Reduced overheating risk: Effective cooling would minimize the risk of overheating and component failures, enhancing the machine’s reliability and lifespan.

- Optimized performance: Improved cooling would allow the machine to operate at its full potential, maximizing productivity and efficiency.

Call to Action:

Are you facing challenges in optimizing the cooling performance of your construction equipment? CFD simulations can provide valuable insights and help you design more efficient and reliable machines. Contact us today to discuss your specific needs and discover how CFD can benefit your product development process.