Industry: Automotive, Off-Highway

Applocations: Powerpack/Powerplant

Challenge: In various industrial applications, air-to-liquid heat exchangers play a critical role in transferring heat from a hot fluid (often air) to a cooler liquid for temperature control. However, achieving optimal heat transfer performance can be challenging due to factors like:

- Limited space: Compact designs can restrict airflow and heat exchange efficiency.

- Fin geometry: Fin design significantly impacts air-to-liquid contact and heat transfer.

- Material selection: Choosing the right materials for fins and tubes balances heat conductivity with cost and weight.

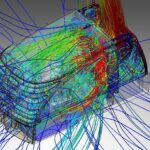

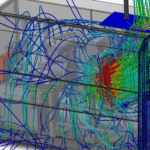

Solution: Computational fluid dynamics (CFD) simulations provide a powerful tool for analyzing and optimizing air-to-liquid heat exchanger performance. This allows engineers to:

- Create virtual models: Develop detailed 3D models of the heat exchanger, including fin geometries, tube configurations, and surrounding components.

- Simulate airflow patterns: Replicate real-world airflow conditions, considering factors like air velocity, temperature, and turbulence.

- Analyze heat transfer: Evaluate the effectiveness of heat exchange between air and liquid, identifying areas of low efficiency or potential bottlenecks.

- Optimize heat exchanger design: Based on CFD results, refine fin geometry, tube layout, and material selection to maximize heat transfer and minimize pressure drop.

Benefits of CFD Simulations for Air-to-Liquid Heat Exchanger Optimization:

- Virtual Testing Environment: CFD eliminates the need for costly physical prototypes and testing, saving time and resources.

- Detailed Flow Insights: CFD provides a comprehensive understanding of airflow patterns and heat transfer phenomena within the heat exchanger, revealing areas for improvement.

- Predictive Capabilities: CFD can predict heat exchanger performance under varying operating conditions, allowing for proactive design optimization.

- Design Optimization: By analyzing the impact of design parameters on performance, engineers can optimize heat exchangers for enhanced heat transfer efficiency and reduced pressure drop.

Outcomes:

CFD simulations can significantly improve air-to-liquid heat exchanger design and performance by:

- Enhanced Heat Transfer: Optimized designs lead to increased heat exchange between air and liquid, ensuring efficient temperature control.

- Reduced Energy Consumption: Improved heat transfer efficiency can lead to lower energy consumption for cooling or heating processes.

- Compact Design Optimization: CFD allows engineers to achieve optimal performance even with space constraints.

- Material Selection Optimization: CFD simulations help identify the most cost-effective materials that meet the required heat transfer characteristics.

Impact on Various Industries:

Implementing CFD simulations for air-to-liquid heat exchanger optimization offers advantages across several industries:

- Power Generation: Optimized heat exchangers in power plants enhance cooling efficiency of critical components, leading to increased power output and reduced operating costs.

- HVAC Systems: CFD simulations help design efficient air-to-liquid heat exchangers for air conditioners and heating systems, leading to improved building comfort and energy savings.

- Automotive: Optimized air-to-liquid heat exchangers in vehicles ensure efficient cooling of engines and radiators, enhancing performance and fuel economy.

- Chemical Processing: CFD plays a crucial role in designing heat exchangers for chemical reactions, ensuring optimal temperature control for efficient and safe operations.

Call to Action:

Are you facing challenges in optimizing the performance of your air-to-liquid heat exchangers? Our engineering team can help! We leverage advanced CFD simulation techniques to analyze and optimize heat exchanger designs, leading to:

- Enhanced Heat Transfer Efficiency

- Reduced Energy Consumption

- Compact and Cost-Effective Designs

- Improved System Reliability

Contact us today to discuss your specific needs and discover how CFD simulations can benefit your air-to-liquid heat exchanger design process.