Description

Find the outer (convex) surface tangential (q – q) stress at point E (refer below figure) of cylindrical shell with two load cases

as follow.

- Uniform normal edge moment, on DC, of 1.0 kNm/m

- Uniform outward normal pressure, at mid-surface ABCD, of 0.6 MPa. Tangential outward normal pressure, on edge DC, of 60.0 MPa

Reference

- Test LE2 from NAFEMS report TSBM, Publication NNB, Rev. 3, NAFEMS Linear Benchmarks, 5 Oct 1990.

Analysis type

Linear Static Analysis

Technologies used

- Meshing: Gmsh, NetGen

- Solver: Calculix

Geometry

Load assumptions

Boundary conditions

- Edge AB, all translations and rotations zero

- Edge AD and Edge BC, symmetry around rq plane, e.g. z translations and normal rotations are all zero

Material properties

Isotropic, E = 210 GPa, ν = 0.3

Computation target

Results

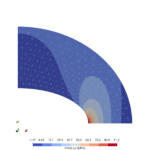

Case 1

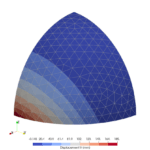

Case 2

Summary

| Case | Theory | Gmsh+CalculiX | Error |

| 1 | 60.0 MPa | 60.97 MPa | 1.62 % |

| 2 | 60.0 MPa | 62.49 MPa | 4.15 % |

| Case | Theory | NetGen+CalculiX | Error |

| 1 | 60.0 MPa | 59.47 MPa | -0.88 % |

| 2 | 60.0 MPa | 62.64 MPa | 4.40 % |

Conclusion

CalculiX results are comparable with theoretical results.