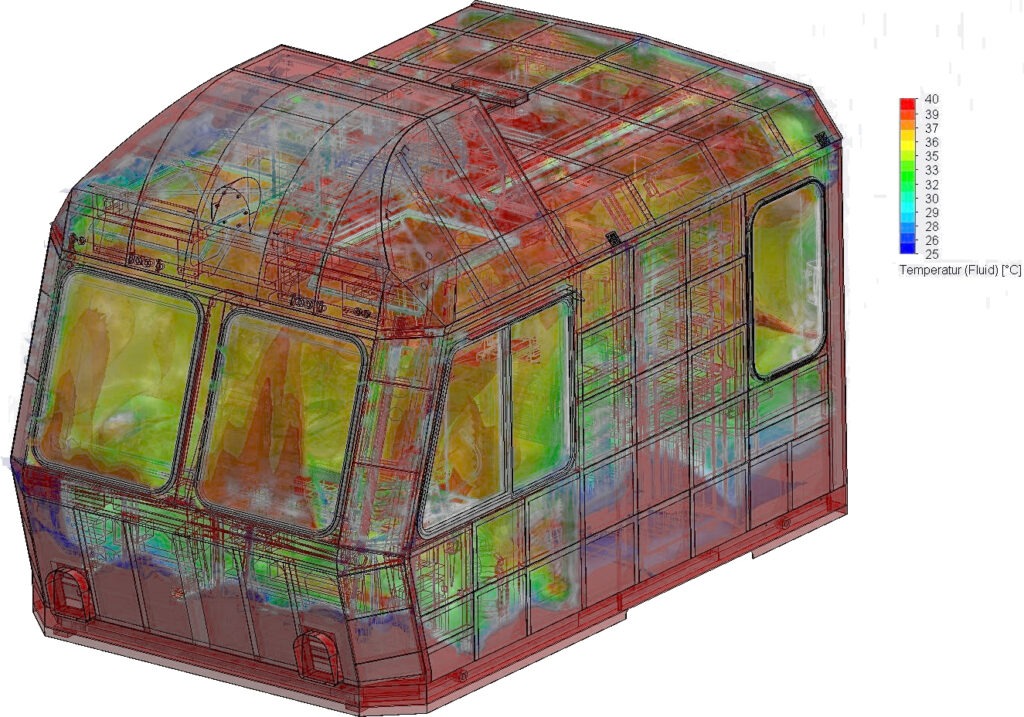

Optimizing Thermal Comfort in a Driver’s Cabine

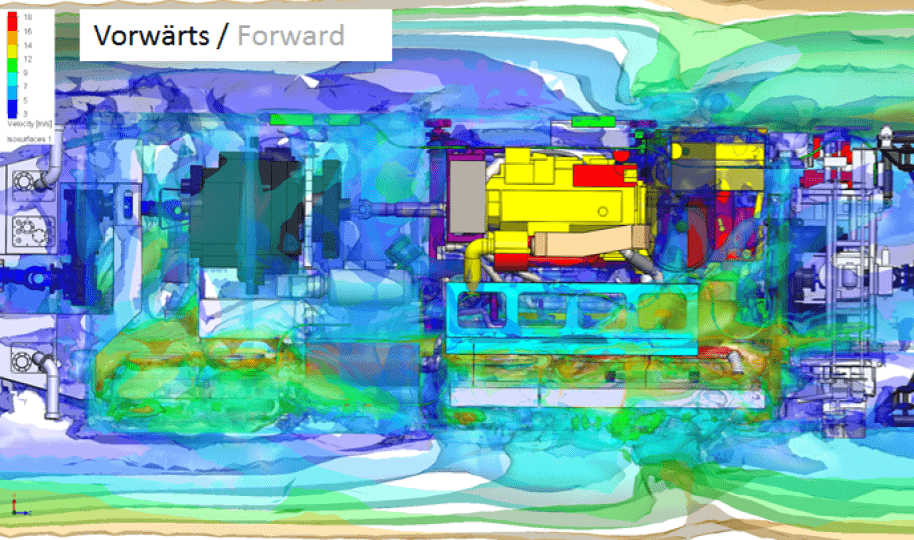

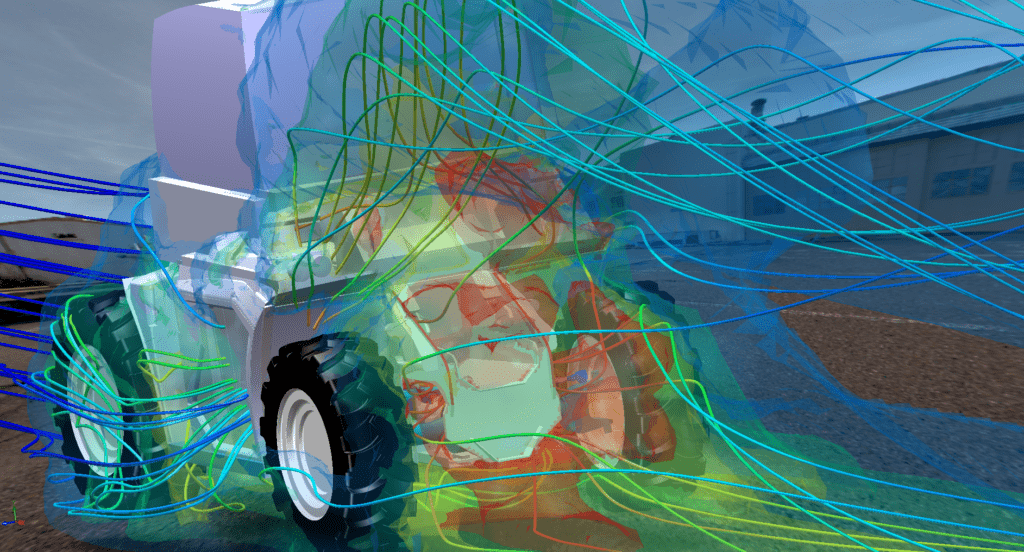

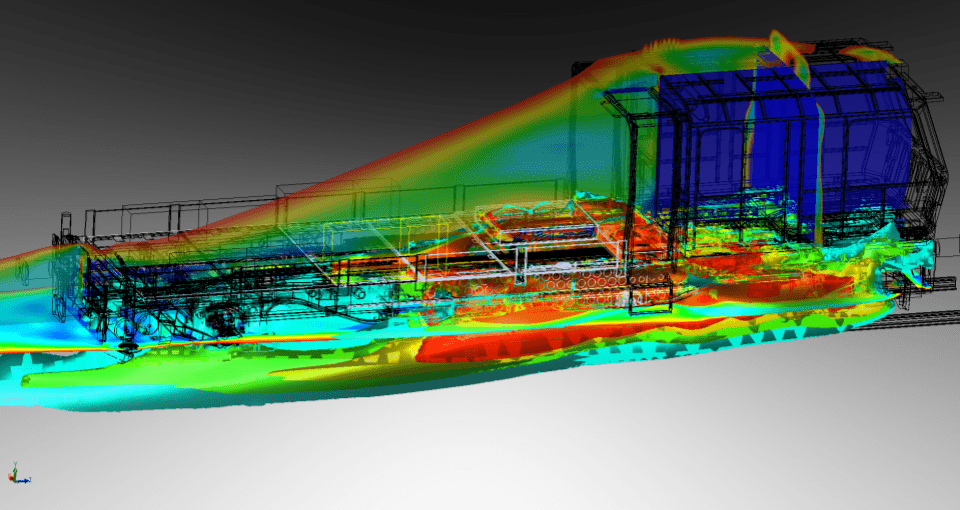

Industry: Rail Transportation Challenge: Maintaining a comfortable working environment for train drivers across diverse weather conditions while adhering to the stringent thermal comfort regulations outlined in EN 14813-1. This standard ensures optimal driver well-being and alertness for safe train operation. Solution: Our team of engineers employed advanced computational fluid dynamics (CFD) simulations to meticulously analyze […]