Optimizing Compressed Air Conveyor Cooling with Early-Stage CFD Analysis

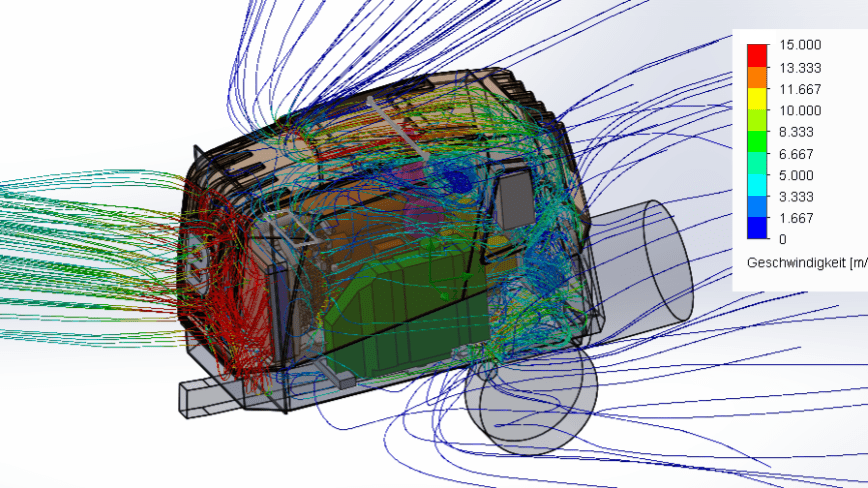

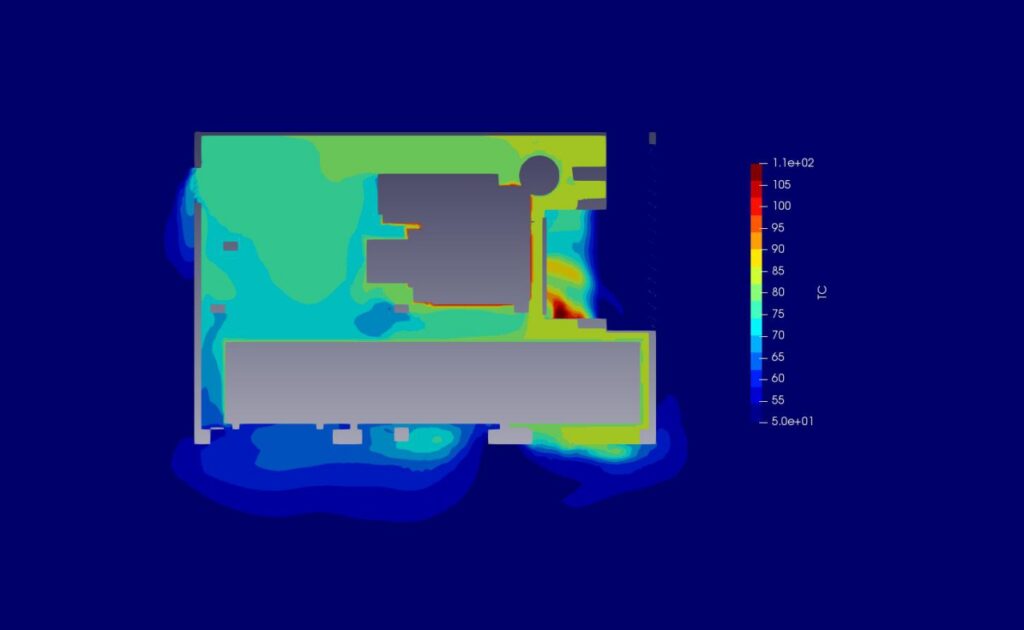

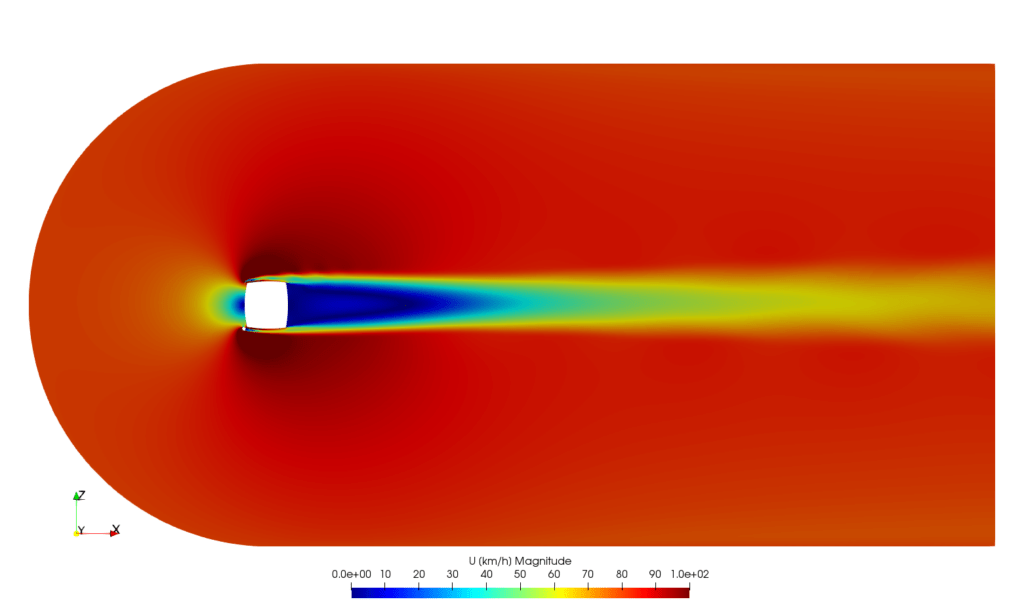

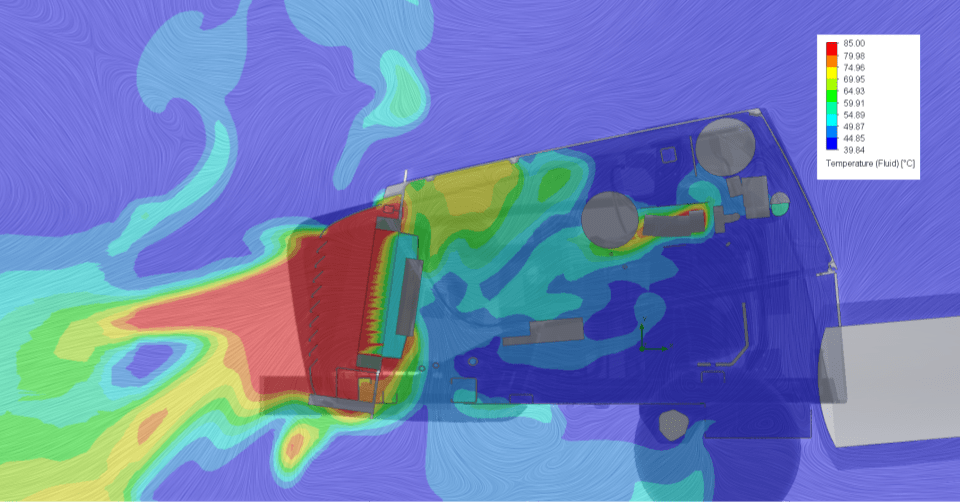

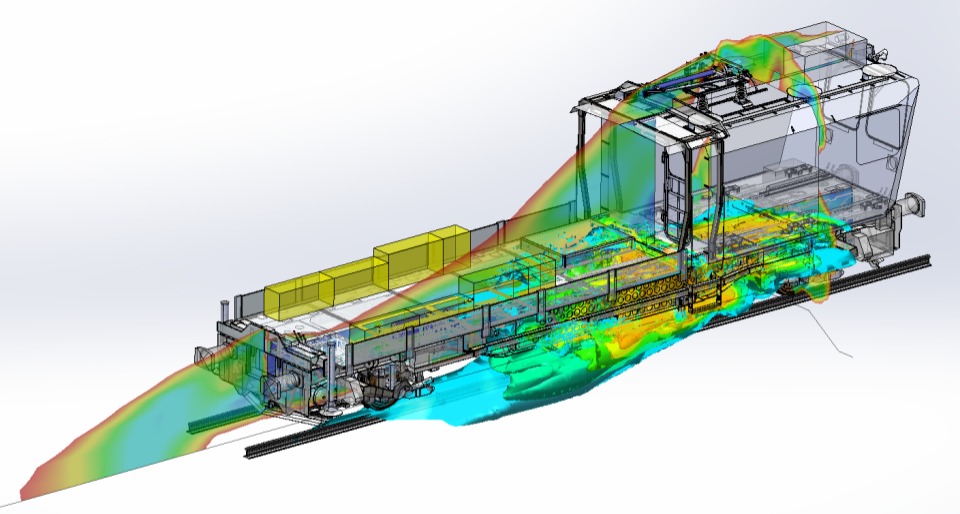

Industry: Construction Equipment Challenge: During the design phase of a new compressed air conveyor, engineers aimed to proactively ensure efficient cooling performance. Traditional methods like physical prototypes can be time-consuming and expensive at this early stage. Solution: Computational fluid dynamics (CFD) simulations were employed to analyze potential airflow patterns, pressure distribution, and temperature distribution within […]