Industry: Off-Highway Equipment, Construction Equipment, Concrete Pumps

Challenge: Manufacturers of off-highway equipment face constant pressure to improve the efficiency and reliability of their machines. A critical factor is ensuring optimal cooling system performance, especially in harsh operating environments. Traditional design approaches often rely on physical prototyping and testing, which can be time-consuming and expensive.

Solution: Advanced computational fluid dynamics (CFD) simulations offer a powerful alternative for optimizing cooling systems. Our engineering team partnered with a leading off-highway equipment manufacturer to analyze the thermal performance of their cooling system.

Benefits of CFD Simulations:

- Virtual Testing Environment: CFD simulations create a virtual environment replicating real-world operating conditions. This allows engineers to:

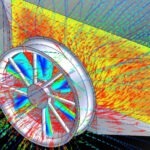

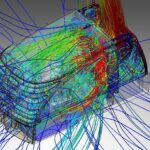

- Analyze air flow patterns and identify areas of inefficiency.

- Evaluate temperature distribution across critical components.

- Virtually test design modifications for component placement, air intake/exhaust locations, and cooling fan performance.

- Improved Design Decisions: By analyzing various scenarios, CFD simulations provide valuable insights to optimize cooling system design for:

- Enhanced cooling capacity: Ensuring the system effectively maintains optimal operating temperatures under varying loads and environments.

- Reduced fan power consumption: Minimizing energy consumption required by the cooling fan for desired cooling performance.

Outcomes:

The CFD analysis in this project led to the identification and implementation of key cooling system improvements:

- Optimized Air Flow Path: Strategic adjustments to air intake and exhaust locations achieved a more uniform distribution of cool air across heat-generating components.

- Reduced Pressure Losses: Redesigning specific components like ducts and louvers significantly reduced pressure losses within the system, allowing for improved air flow with less fan effort.

- Strategic Component Placement: Utilizing CFD data, engineers positioned key cooling system elements (heat exchangers, fan) for optimal heat transfer from components to the cooling air.

Impact on Off-Highway Equipment:

Implementing a CFD-optimized cooling system design can lead to significant benefits for off-highway equipment:

- Enhanced Equipment Reliability: Improved cooling performance reduces thermal stress on critical components, extending their lifespan and minimizing overheating-related failures.

- Reduced Maintenance Costs: By ensuring optimal operating temperatures, the optimized cooling system contributes to lower maintenance requirements.

- Increased Operational Efficiency: Lower fan power consumption translates to improved fuel efficiency or increased power available for other machine functions.

Are you facing challenges in optimizing the cooling system performance of your off-highway equipment? We can help!

Our team of CFD experts leverages advanced simulation techniques to analyze and improve cooling system designs, leading to:

- Enhanced equipment reliability

- Reduced maintenance costs

- Increased operational efficiency

Contact us today to discuss your specific needs and discover how we can help you create more efficient and reliable off-highway equipment.

This case study exemplifies how CFD simulations offer a valuable tool for optimizing cooling systems in off-highway equipment. By creating a virtual environment to analyze air flow and heat transfer, engineers can design more efficient cooling systems, leading to enhanced performance, reliability, and cost savings for manufacturers and operators alike