Industry: Agricultural Equipment

Challenge: This study aimed to optimize the design of an intake manifold for a specified vehicle model. The goal was to improve airflow characteristics, minimize drag forces, and reduce side force oscillations experienced by the vehicle.

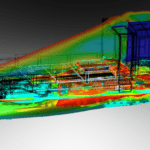

Solution: Computational fluid dynamics (CFD) simulations were employed to analyze the performance of six different intake manifold geometries.

Results and Discussion:

CFD simulations revealed the impact of geometry modifications on the intake manifold’s performance:

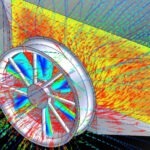

- Improved Airflow: Visualizations of airflow patterns within the manifold helped identify designs that promoted better air flow, potentially enhancing engine performance.

- Reduced Drag: The analysis allowed for comparison of the aerodynamic drag generated by each variant. Variant 3 “Wide-Opening” exhibited the lowest drag coefficient (Cd), indicating a significant reduction in drag forces. This translates to improved fuel efficiency.

- Minimized Side Force Oscillations: The CFD analysis assessed the wake stability for each design. Variant 3 “Wide-Opening” demonstrated a more stable and less turbulent wake, contributing to minimized drag fluctuations, potentially leading to a more stable and predictable driving experience.

Optimal Design Selection:

Based on the CFD results, Variant 3 “Wide-Opening” emerged as the optimal design for the intake manifold. This variant offered several key benefits:

- Improved Airflow: The geometry changes facilitated better airflow through the intake manifold, potentially enhancing engine performance.

- Reduced Drag: The lower Cd value translated to reduced aerodynamic drag, contributing to improved fuel efficiency.

- Minimized Side Force Oscillations: The stable wake characteristics minimized side force oscillations, potentially leading to a more stable and predictable driving experience.

Conclusion:

This case study demonstrates the effectiveness of CFD analysis in optimizing the design of intake manifolds. By analyzing airflow patterns, drag forces, and wake characteristics, engineers can develop intake manifolds that promote better engine performance, fuel efficiency, and vehicle stability.

Are you facing challenges in optimizing the aerodynamic performance of your automotive components?

CFD simulations can provide valuable insights, allowing for the design of components that are both efficient and contribute to a superior driving experience. Contact us today to discuss how our expertise in CFD analysis can help you achieve your design goals.