Industry: Construction Equipment

Challenge: During the design phase of a new compressed air conveyor, engineers aimed to proactively ensure efficient cooling performance. Traditional methods like physical prototypes can be time-consuming and expensive at this early stage.

Solution: Computational fluid dynamics (CFD) simulations were employed to analyze potential airflow patterns, pressure distribution, and temperature distribution within virtual models of various enclosure configurations for the compressed air conveyor. This allowed engineers to:

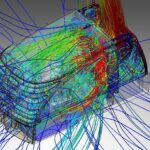

- Develop virtual models: Create detailed 3D models of the conveyor, including heat sources (e.g., compressor, motor), cooling components (e.g., coolers), and different enclosure designs.

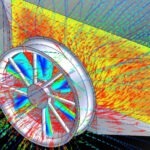

- Simulate airflow: Replicate real-world operating conditions, considering factors like air temperature, heat transfer, and turbulence.

- Analyze pressure drop: Identify areas of high resistance and quantify the pressure losses within the enclosure.

- Evaluate thermal performance: Assess the effectiveness of heat removal from various components, ensuring optimal cooling is achieved.

Benefits of Early-Stage CFD Simulations:

- Proactive Design Optimization: Identify and address potential cooling inefficiencies before physical prototypes are built, saving time and resources.

- Virtual Testing Environment: CFD eliminates the need for costly physical modifications and testing, allowing for exploring design iterations efficiently.

- Detailed Thermal Insights: CFD provides a comprehensive understanding of airflow patterns, pressure distribution, and temperature distribution within the enclosure, revealing areas for improvement.

- Predictive Capabilities: CFD can predict the impact of design changes on cooling performance, enabling proactive optimization before physical construction.

Investigated Enclosure Variants:

The CFD simulations analyzed the impact of different enclosure configurations on airflow and cooling:

- Baseline (Ist-Stand): Standard configuration without modifications.

- Extended Hood: Baseline configuration with an extended hood for increased airflow volume.

- Extended Hood with Openings: Configuration with an extended hood and strategically placed openings to improve air circulation.

- Open Configuration (Hypothetical): Model without an enclosure to establish a theoretical cooling performance benchmark.

Thermal Loads and Boundary Conditions:

- Ambient Temperature: Set at a realistic operating temperature (e.g., 45°C).

- Heat Sources: Defined based on expected component heat generation (e.g., motor, compressor).

- Coolers: Modeled with their heat dissipation capabilities.

CFD Analysis Results:

The CFD simulations identified key factors influencing cooling performance:

- Impact of Enclosure Design: The baseline enclosure design restricted airflow, leading to pressure buildup and reduced cooling effectiveness.

- Benefits of Extended Hood: Extending the hood increased the available air volume within the enclosure, potentially improving airflow.

- Strategic Openings: Implementing strategically placed openings in the enclosure could further enhance air circulation and reduce pressure losses.

- Importance of Enclosure Optimization: Compared to the open configuration (hypothetical), all enclosed variants exhibited some degree of cooling inefficiency. However, CFD analysis allowed for identifying the most efficient enclosure design among the investigated options.

Proposed Design Optimization:

Based on the CFD results, engineers could propose design modifications to optimize the enclosure for improved cooling:

- Hood Extension: Implementing an extended hood with a strategically determined length to balance airflow volume and enclosure size.

- Optimized Opening Placement: Strategically positioning openings in the enclosure to facilitate air intake and exhaust, ensuring proper air circulation.

- Impeller Design Considerations: If necessary, exploring impeller design modifications to enhance airflow characteristics within the chosen enclosure configuration.

Benefits of Early-Stage CFD Analysis:

By using CFD simulations in the early design stage, engineers were able to:

- Proactively optimize the enclosure design for enhanced cooling efficiency and reduced pressure losses.

- Minimize the risk of overheating by ensuring adequate cooling of critical components.

- Reduce development time and costs by identifying and addressing potential cooling inefficiencies before physical prototypes are built.

- Deliver a more reliable and efficient compressed air conveyor with optimal thermal performance.

Ready to get started?:

Are you facing challenges in designing thermally efficient industrial equipment? Early-stage CFD simulations can provide valuable insights and help you optimize your designs for optimal performance and reliability. Contact us today to discuss how CFD can benefit your product development process.